In today’s fast-paced construction landscape, collaboration is more than a buzzword — it’sa necessity. Early Contractor Involvement (ECI) is increasingly becoming a strategic advantage, especially in precast concrete projects, where precision, timing, and planning are key to success. Byengaging contractors and key stakeholders early in the design process, teams can unlock efficiencies, reduce risks, and deliver projects on time and within budget.

What is Early Contractor Involvement (ECI)?

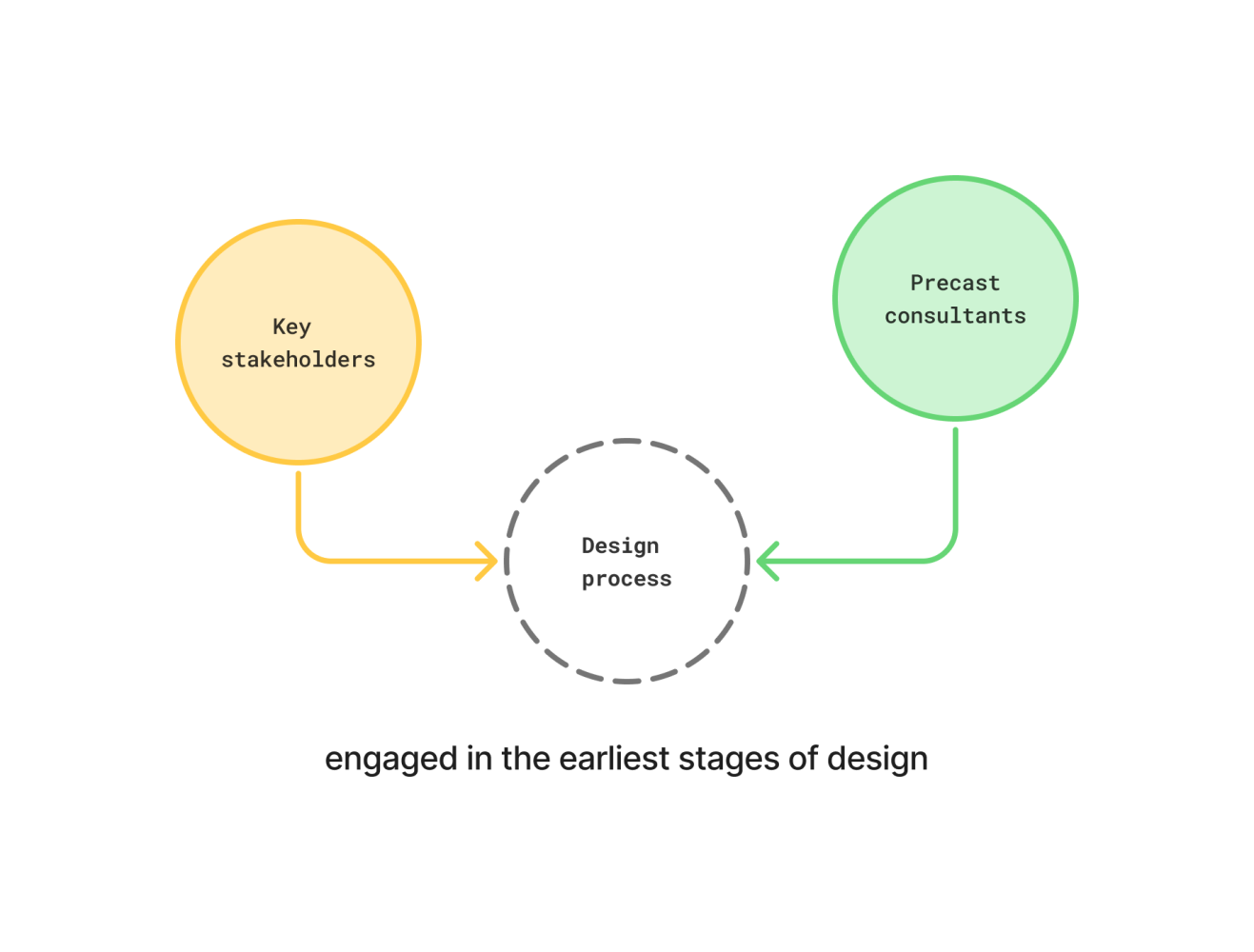

ECI is a procurement approach where contractors and key stakeholders, including precast consultants, arebrought into the design process at an early stage. This allows for shared expertise, better risk management, and more informed decision-making before construction begins.

Unlike traditional methods where contractors are brought in after design completion, ECI encourages active participation during design development. This early collaboration helps align design intent with practical execution capabilities, ensuring that the project is both buildable and cost-effective from the outset.

The ECI Process: A Collaborative Workflow

typically unfolds in several key stages:

- Early Engagement: Contractors and precast specialists join the design team during conceptual or schematic design phases.

- Collaborative Design Review: Teams work together to assess design feasibility, manufacturing constraints, and construction logistics.

- Risk Identification and Mitigation: Potential risks—such as lifting logistics, transport challenges, or site constraints—are identified and addressed early.

- Cost and Schedule Alignment: Cost engineers develop realistic budgets based on actual production rates and lead times, while planners create achievable timelines.

- Ongoing Coordination: Continuous collaboration throughout design refinement and into construction ensures that emerging issues are resolved proactively.

Why ECI Matters in Precast Concrete Projects

Precast concrete construction demands precision and coordination, making ECI particularly valuable. Here’s why:

1. Optimized Design for Manufacturing

Early involvement of precast engineers ensures that structural elements are designed with manufacturing efficiency in mind. This approach reduces the need for costly redesigns and minimizes production delays. For example, coordinating the placement of lifting anchors and designing for mold reuse during early design phases can significantly reduce fabrication costs and improve turnaround times.

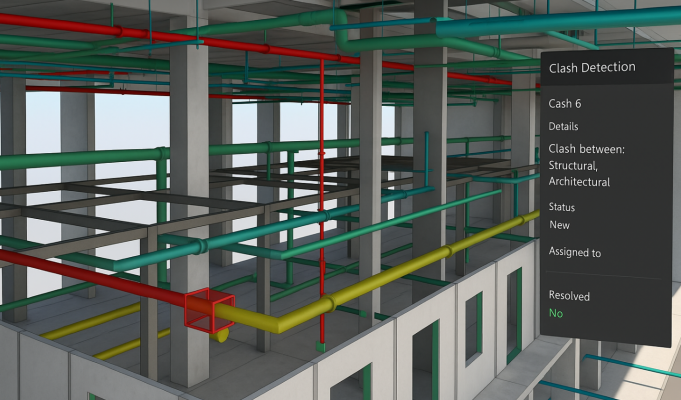

2. Improved Coordination and Clash Avoidance

When contractors, architects, and precast designers collaborate from day one, potential clashes between structural, mechanical, and architectural elements can be detected and resolved digitally using Building Information Modeling (BIM). This proactive clash detection leads to cleaner installations on site, fewer delays, and reduced rework costs.

3. Accurate Cost Estimation and Program Planning

Early alignment between design intent and construction capabilities allows cost engineers to base estimates on actual precast production rates rather than assumptions. Knowing lead times, formwork cycles, and site constraints upfront enables realistic budgeting and scheduling, reducing the risk of cost overruns and program delays.

4. Risk Reduction and Shared Accountability

ECI fosters a shared understanding of project risks among all stakeholders. By engaging early, the project team can agree on technical solutions, sequencing, and mitigation strategies before issues become critical. For example, planning for crane access, lifting logistics, and potential weather delays early in the process helps avoid costly last-minute changes.

Challenges and Considerations in Implementing ECI

While ECI offers many advantages, it is not without challenges:

- Increased Upfront Planning: Early collaboration requires more time and resources during design phases, which may be difficult for projects with tight initial schedules.

- Stakeholder Commitment: Successful ECI depends on the willingness of contractors, designers, and owners to engage early and share information transparently.

- Potential Conflicts: Early involvement of multiple parties may lead to disagreements on design or cost issues that require skilled facilitation to resolve.

- Not Always Suitable: For very small or straightforward projects, the benefits of ECI may not justify the additional effort and cost.

Acknowledging these challenges helps set realistic expectations and encourages thoughtful application of ECI.

The Future: Integrating ECI with Digital Workflows

The power of ECI is amplified by advances in digital construction technologies. Tools like BIM, cloud-based collaboration platforms, and real-time data sharing enable teams to work smarter and faster. For precast concrete projects, integrating 3D modeling with prefabrication expertise allows for:

- Enhanced visualization and clash detection

- Streamlined communication across dispersed teams

- Real-time updates on production status and site conditions

- Data-driven decision-making for sustainability and cost control

As these technologies become standard practice, ECI will continue to evolve as a cornerstone of efficient, sustainable construction.

Early Contractor Involvement is transforming precast concrete construction by fostering collaboration, reducing risks, and improving project outcomes. While it requires commitment and upfront investment, the benefits in terms of optimized design, cost savings, and smoother execution are substantial. By integrating ECI with digital workflows, construction teams can build smarter, faster, and more sustainably—meeting the demands of today’s complex projects and tomorrow’s innovations.